Advanced Machining Center: The Perfect Combination of Precision and Efficiency

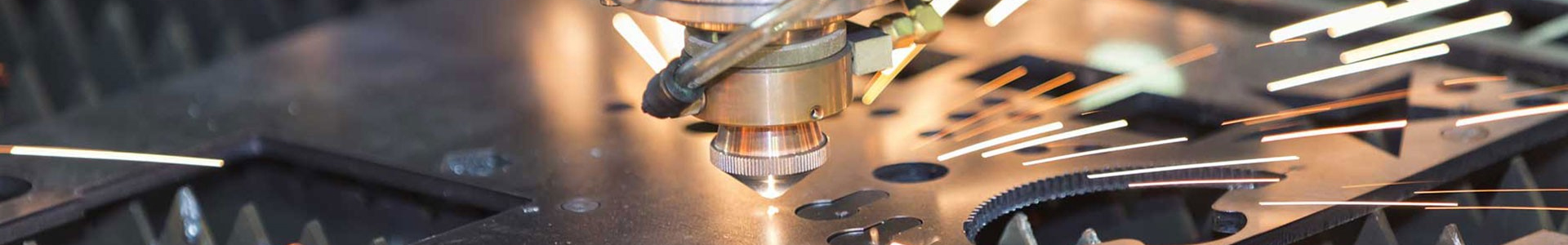

In modern manufacturing, machining centers play a vital role. They are the key equipment for transforming raw materials into high-precision and high-quality components. Today, let's step into a machining center equipped with 12 advanced devices to deeply understand their outstanding performance in the field of metal processing.

This machining center is equipped with a diverse range of equipment, including CNC (Computer Numerical Control) machines, lathes, 3D laser cutting machines, and CNC milling machines, capable of meeting various complex processing needs. Whether it is No. 45 steel plate, chromium 12, cast iron, or aluminum, all can be meticulously processed into products that meet strict standards with the help of these devices.

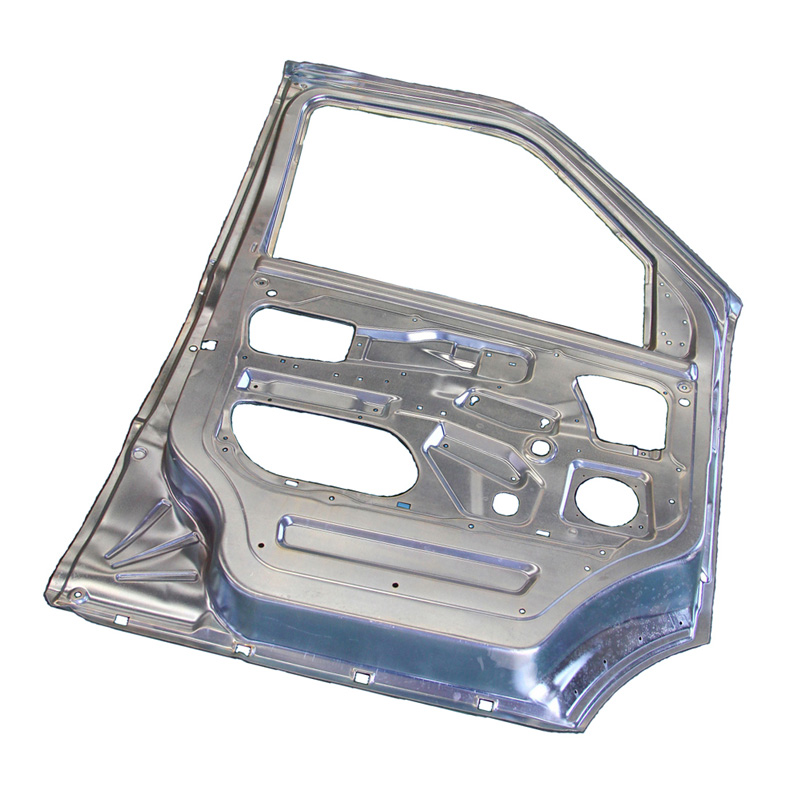

Among them, the processing of No. 45 steel plates fully demonstrates the powerful capabilities of the machining center. No. 45 steel plates have good comprehensive mechanical properties and are widely used in the manufacturing of various mechanical parts. Under the precise operation of the machining center, they can be processed into various shapes and sizes of components, providing a solid foundation for all kinds of mechanical equipment.

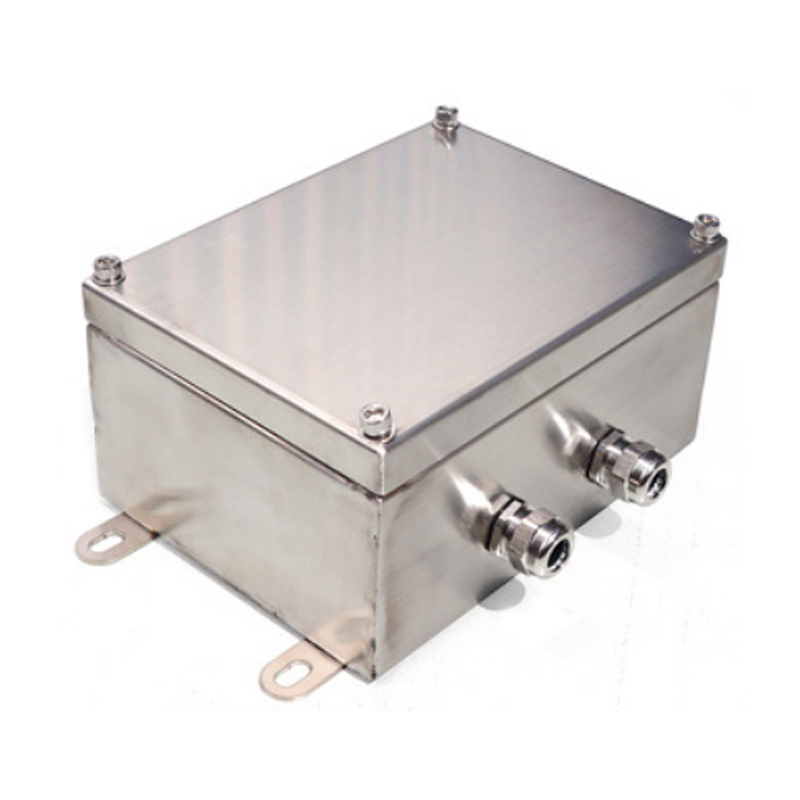

Chromium 12 is a material with high hardness and wear resistance, often used in the manufacturing of molds and other products that have extremely high requirements for precision and durability. With its exquisite craftsmanship and high-precision equipment, the machining center can process chromium 12 perfectly, ensuring the quality and service life of the molds.

Cast iron materials have good casting performance and shock absorption properties and are often used in the manufacturing of large structural components such as machine tool beds. When processing cast iron in the machining center, it can overcome the characteristics of high hardness and difficult processing to ensure that the processed products have a smooth surface and accurate dimensions.

Aluminum is favored for its lightweight, high strength, and good electrical conductivity. Under the deft hands of the machining center, aluminum is processed into various precision components and is widely used in aerospace, automotive manufacturing, and other fields.

It is worth noting that these devices can process materials with a thickness of 200 - 300 millimeters. This processing capacity provides strong support for the manufacturing of large components. In actual production, such a processing thickness range can meet the needs of many industrial fields and provides the possibility for manufacturing large machinery and equipment.

In terms of precision, it is a major highlight of this machining center. The precision of the equipment is set at 0.02 millimeters, and the actual operating precision of the vertical lathe can even reach 0.01 millimeters. Such high precision means that the processed components can perfectly match the design requirements, reducing assembly errors and improving the quality and performance of the products.

In actual operation, each device is operated and monitored by experienced technicians. They are proficient in various processing techniques and parameter settings and can formulate the best processing plan according to different materials and processing requirements. At the same time, the machining center is also equipped with advanced detection equipment to conduct strict detection and quality control on the processed components to ensure that each product meets the high-precision standards.

To maintain the good performance and precision of the equipment, the machining center has also established a perfect maintenance system. Regular inspections, cleaning, lubrication, and debugging of the equipment are carried out, and worn parts are replaced in a timely manner to ensure that the equipment is always in the best working condition. Moreover, the center also pays attention to the training and skill improvement of employees, continuously improving the technical level and sense of responsibility of the operators to ensure the stability and reliability of the processing process.

In today's highly competitive market environment, this machining center with 12 advanced devices has won the trust and praise of customers with its high precision, high efficiency, and diverse processing capabilities. It not only provides a strong guarantee for the development of the enterprise itself but also contributes to the advancement of the entire manufacturing industry.

In the future, with the continuous advancement of technology and the changing market demands, machining centers will continue to innovate and upgrade. We have reason to believe that it will achieve greater breakthroughs in precision and efficiency, bringing more surprises and possibilities to the manufacturing industry. At the same time, machining centers will also pay more attention to green environmental protection and sustainable development, adopting more energy-saving and efficient processing techniques and equipment to reduce the impact on the environment. Let's wait and see and look forward to the more brilliant achievements of this machining center in the future!