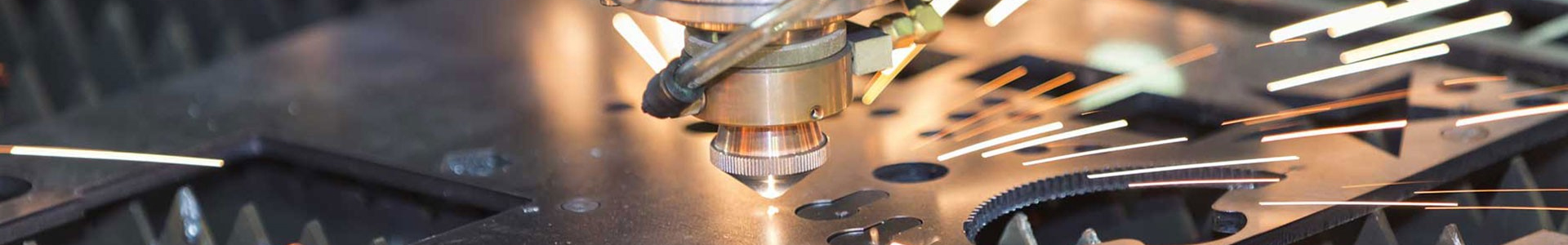

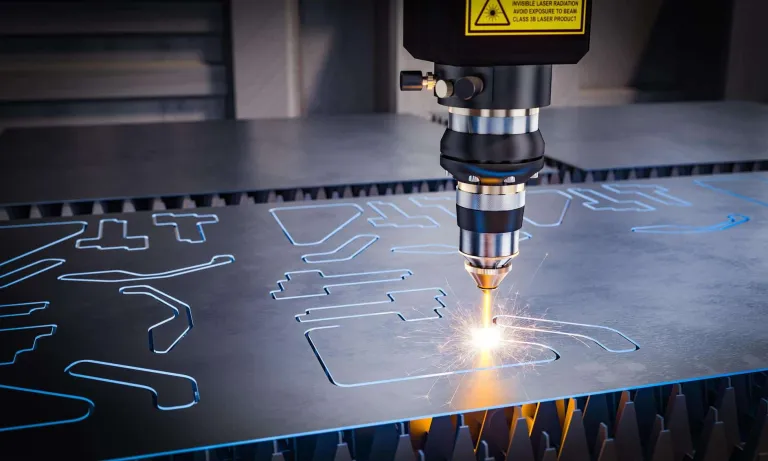

Laser cutting is a versatile process proficient in cutting a range of materials, including metals, plastics, wood, and more. Renowned for its precision, the method allows for intricate designs with minimal wastage. Offering swift production, clean cuts, and adaptability to diverse materials, laser cutting stands out as a cost-effective, efficient, and environmentally friendly solution.

What is the benefit of Laser Cutting Services?

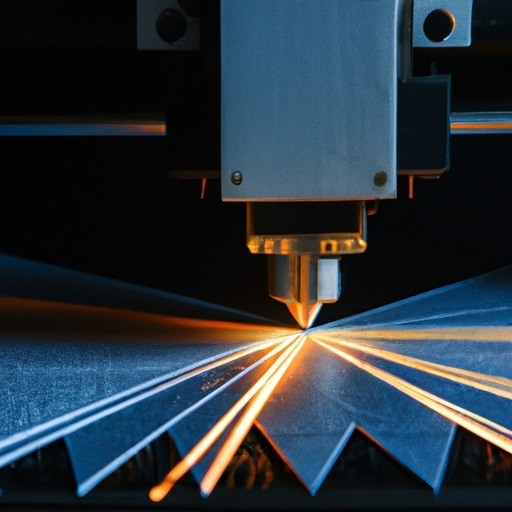

Laser is an acronym for Light Amplification by Stimulated Emission of Radiation. By focusing an intensely concentrated and powerful beam of light through a lens, a laser is produced that can cut through materials. The cutting action originates from melting and/or erosion at the location of the laser and metal interface.

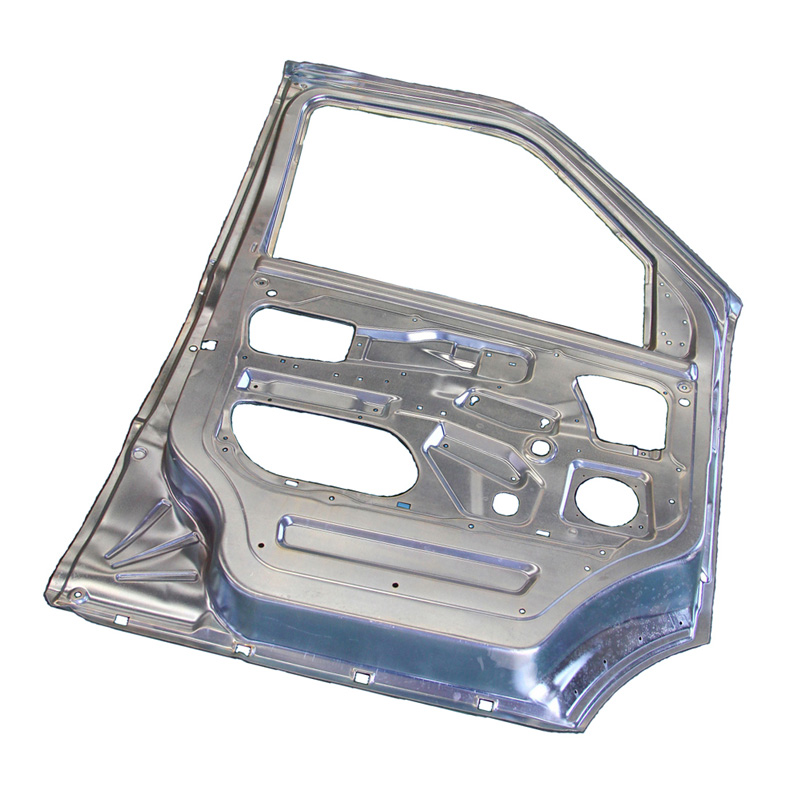

From engravings to cutting through metal entirely, laser cutting opens a variety of designs from prototyping and testing to full-scale manufacturing production lines.

What are the advantages of Laser Cutting Services?

With laser cutting machines, there are several advantages to consider versus similar subtractive manufacturing processes such as CNC machines:

·Precision: The amount of kerf, or material that is burned away, is substantially smaller when laser cutting parts, typically less than 1mm. This translates to more precise cuts versus CNC router bits that are large and produce rounded corners rather than more straightened angles. Because laser cutting machines operate from vector files, they also produce parts that are highly detailed and the closest or exact to the original intended design.

·Speed: Lasers cutting machines do not require the more tedious set-ups of CNC machines; if the material is secure, no clamps are necessary. Clean-up, repeatability, and cycling to another laser cut product are also faster since there is not a large mess of wasted materials. Depending on the diode or laser emitter, the same apparatus can be used again and again without changing heads or bits. There is also little to no post-processing with completed, cut material, as cuts are not rough.

·Operability: The adaptability to cut many designs on a wide array of materials is also a positive. These include dense materials like metals and wood, softer and more delicate materials like cardboard, and thin sheets that can be cut to exacting specifications. Laser cutting machines do not require as much space as CNC machines. The learning curve and trial-and-error phase of operation are also not as steep as CNC machining.