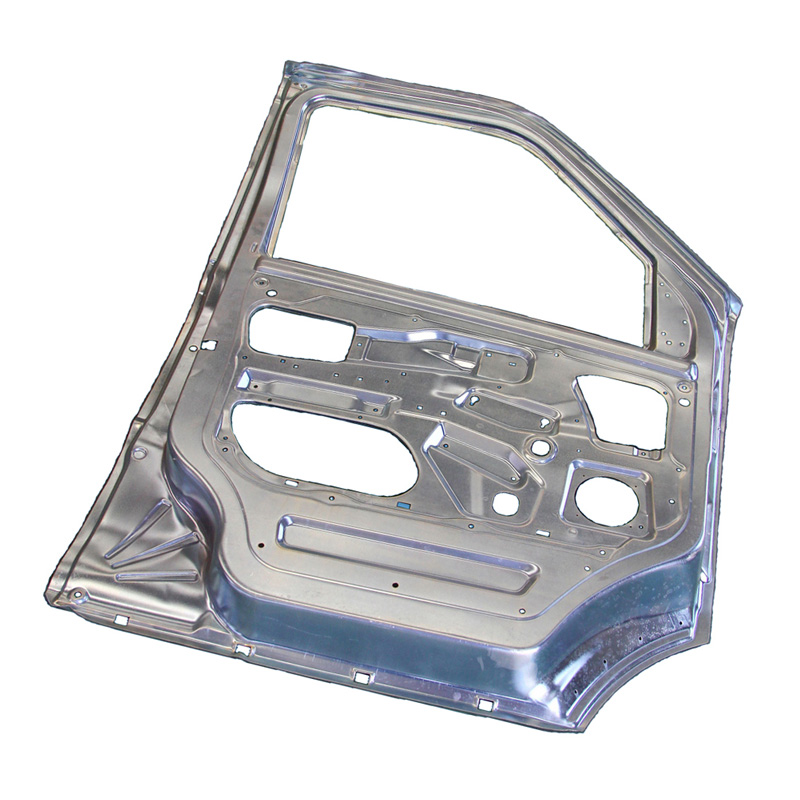

Motor Vehicle Car Body Panel Metal Bumper Stamping

Car body stamping manufacturing processes can quickly and cleanly create solid metal parts and forms. The process uses specialized dies that press sheets of metal into precisely the right form. Xiamen Yulong Machinery benefit from using metal stamping for parts like fenders and hub caps because the dies can be used again to create consistently sized and shaped parts that meet tight specifications and tolerances. Some key benefits of metal stamping include:

Cost-Effectiveness:

Once the dies have been made, manufacturers can create high-volume runs of automotive parts at a low cost. Metal stamping techniques can handle a variety of metals, which allows companies a large degree of flexibility without additional costs. The metal stamping dies themselves are also cost-effective to create and keep in good working condition. The finishing steps of producing the parts, like plating, are also cost-effective.

Material Efficiency:

Metal stamping processes use sheet metal to create parts. Sheet metal is efficient and doesn’t add wasteful heft or thickness to the part. Sheet metal can be used for an array of parts, including structural elements, the chassis, and mechanical components in the engine or transmission systems.

Automation: Metal stamping processes can be handled entirely by machinery. Not only does this reduce the risk of human error or inconsistency, but it also lowers labor costs and keeps employees safe.

Xiamen ZFYL Machinery has the ability for large-scale production and can achieve efficient assembly line operations. We owns 15 production lines with various equipment such as large and medium-sized stamping, machining, and welding equipment, and produces different types of products. Such equipment scale and product variety reflect its strong production capacity, which enables it to produce a large number of stamping parts in a short time to meet the order requirements of automobile manufacturers. Thus, it can reduce production costs and improve market competitiveness.

Advanced equipment and technology: Xiamen Yulong Machinery introduce advanced production equipment and technologies to ensure the quality and precision of products. For example we have purchased world - class welding equipment from Japan.

Mold design and manufacturing capabilities: Our factory with professional mold design and manufacturing teams can conduct R & D, design, and production according to the needs of different customers.. We can quickly design and manufacture suitable molds according to the special requirements of automobile manufacturers, and then produce customized bumper stampings, improving the adaptability and uniqueness of the products.

Raw material control: HigQuality inspection system: A comprehensive quality inspection system is the key to ensuring product quality. We conduct strict quality inspections at every stage of the production process, promptly identifies and resolves issues, ensures that the stamped parts leaving the factory meet relevant standards and requirements, reduces the defective product rate, and enhances customer satisfaction.

Extensive customer resources: Our factory with a good reputation and high - quality products can often attract many automobile manufacturers as their customers. So far our factory has supplied auto parts such as automotive interiors, automobile bumpers, and stamped parts to Guangzhou Automobile Group. (GAG)

On March 19, 2025, GAC Group announced that Huawang Automotive Technology (Guangzhou) Co., Ltd., a new company invested and established by it, was officially established, and a new high - end intelligent vehicle brand would also be announced soon. This is a further layout in the intelligent vehicle ecosystem and high - end brand by GAC Group, and it is also the latest progress of the GH project.

Strong market adaptab

Specification:

| 1.Optional Material: | high strength steel, metal,Aluminum. | |||||

| 2.Process Technologies: | car body stamping | |||||

3.Reachable Tolerance: | 0.01-0.1mm | |||||

| 4.Optional surface treatment: | Zinc plated, Nickel plated,Powder coating,painting,brushed. | |||||

| 5.Sample Making : | Rapid prototype according to customer's drawing. | |||||

| 6.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. | |||||

| 7. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 | |||||

If you have demand for car body stamping services,body panel stamping,motor vehicle metal stamping,bumper stampings, Welcome to contact us, we will provide you best price and good quality product.