From plastic material to stainless steel material CNC machining parts

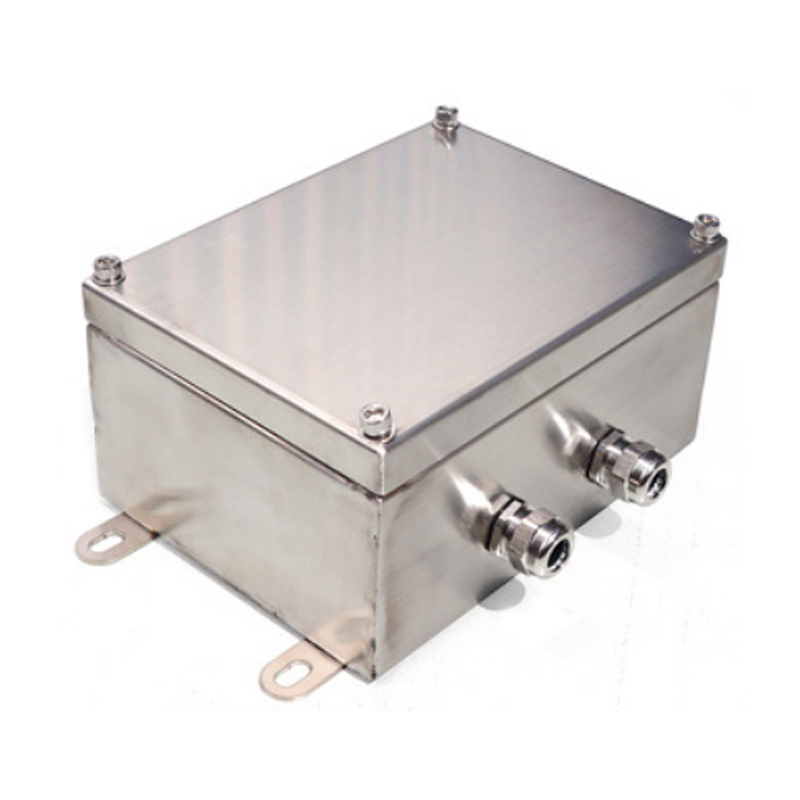

In today's globally competitive manufacturing landscape, companies that can keenly identify customer pain points and deliver innovative solutions stand out. Our team addressed a European client’s initial request for plastic housing brackets by deeply analyzing their unspoken needs, creatively proposing a stainless steel machined parts as alternative, and successfully delivering the first batch after three months of prototyping and testing. Beyond showcasing technical expertise, this case exemplifies how customer-centric innovation translates into commercial success. By dissecting key milestones, technical challenges, and business considerations, we aim to provide a comprehensive reference for customer-driven product development in manufacturing.

Phase 1: Uncovering the True Need – The Hidden Pain Behind Surface Requirements

The client’s initial request was straightforward: plastic housing brackets to support critical components in their high-end electronic devices. Detailed specifications included:

Dimensional tolerance: ±0.05mm

Load requirements: Static load ≥1kg, dynamic load 1kg

Environmental tolerance: Stable performance at −20°C to 60°C

The Cost Breakthrough

Our engineering team identified the client’s unvoiced core issue: mold costs. Traditional plastic brackets required high-precision molds, with estimated tooling expenses reaching €2,000. For medium-volume production, this added €2 per unit, inflating total costs by 10% compared to market alternatives.

Through iterative discussions, we uncovered critical insights:

The client prioritized cost-performance optimization, not material dogma.

The operating environment involved outdoors exposure and vibrations, raising durability concerns for

plastic.

“By the third meeting, we realized their true goal wasn’t plastic itself, but the most functional solution within budget,” recalled Export Manager Song

(Continued in subsequent sections: Design Feasibility, Prototyping, and Production – structured similarly with technical and business insights.)

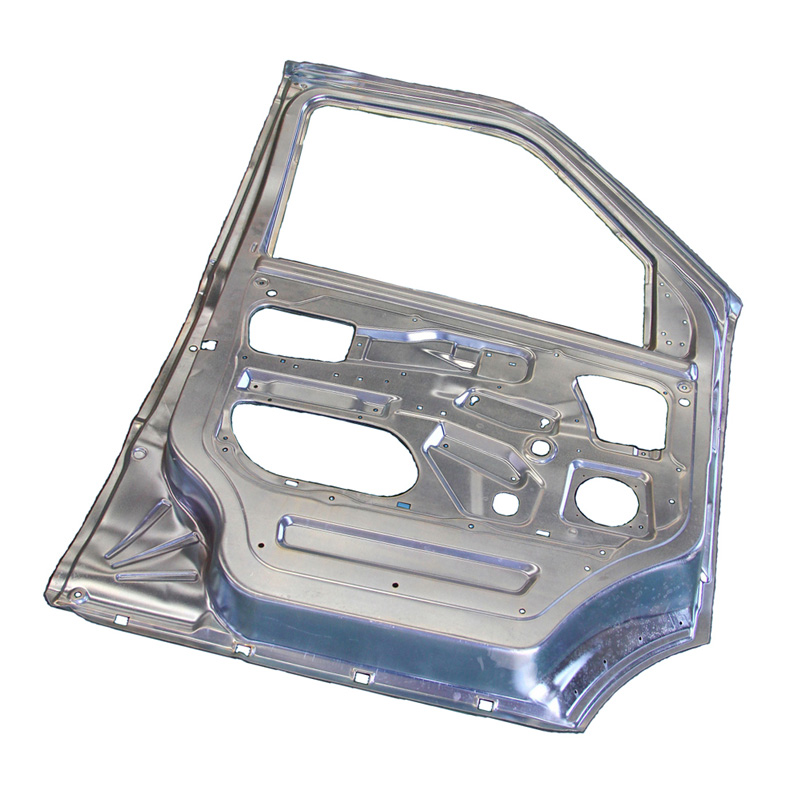

Phase 2: The Birth of an Innovative Solution – Feasibility Study for Stainless Steel Material CNC Machining parts ( Brackets)

1. Cross-Functional Collaboration

Drawing on a profound understanding of the client's underlying needs, our multidisciplinary team – comprising design engineers, materials specialists, and production cost analysts – initiated a comprehensive exploration of alternatives to plastic. Following two weeks of intensive research and conceptual evaluation, the stainless steel machining solution emerged as the optimal choice.

2. Scientific Material Selection Process

We conducted a rigorous comparative analysis of three potential alternative materials:

Comprehensive Advantages of Stainless Steel Machining Solution

(1) Optimized Cost Structure

Complete elimination of mold costs (€120,000 initial savings)

Despite higher per-unit machining cost (€3.8/unit), total cost reduction of 18% compared to plastic solution at projected annual volume

(2) Enhanced Performance Characteristics

Yield strength: 8-10× greater than engineering plastics

Fatigue resistance: Exceptional durability with 3× extended product lifecycle

(3) Seamless Supply Chain Integration

Leveraged client's existing stainless steel surface treatment network (sandblasting + passivation)

No additional supply chain complexity introduced

The success of this case has opened new horizons for our "Material Substitution Consulting" service line. Three European clients have already initiated discussions for similar collaborative projects. This development underscores a pivotal industry shift:

Key Industry Transition:

Manufacturing competitiveness is evolving from pure production capacity to solution design capability – a transformation that begins with deeply understanding even the most seemingly straightforward client requirements.

Service Diversification

Establishes us as value-added partners beyond traditional manufacturing

Market Validation

Early European interest confirms demand for technical-commercial hybrid solutions

Competitive Differentiation

Positions us at the forefront of the manufacturing-as-a-service (MaaS) revolution