1. Design & Programming

- 3D Modeling: Use CAD software (such as SolidWorks, UG/NX) for product structure design.

- DFM Analysis: Conduct design for manufacturability analysis to optimize the design, reducing processing difficulty and costs.

- CNC Programming: Based on the 3D model, use CAM software to write processing programs (G-code) for CNC machine tools.

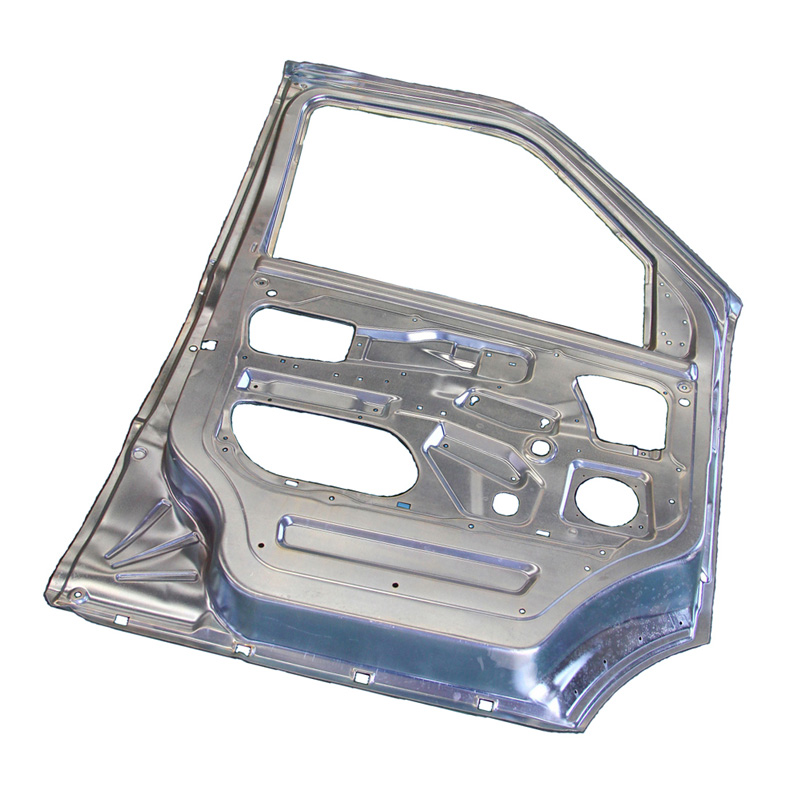

2. Sheet Metal Forming - Applicable to Thin-Walled Casings

- Laser Cutting: Use high-power laser cutting machines to cut stainless steel sheets into the required flat shapes, featuring high precision and fast speed.

- Stamping: Use dies on punch presses for forming operations such as punching, corner cutting, and drawing, suitable for mass production.

- Bending: Use bending machines with precision dies to bend flat sheets into three-dimensional shapes, forming the basic structure of the casing.

- Welding: Weld the edges that need to be joined after bending. TIG welding (argon arc welding) is commonly used to obtain aesthetically pleasing and strong welds. Laser welding is also becoming increasingly popular, with a small heat-affected zone, minimal deformation, and finer welds.

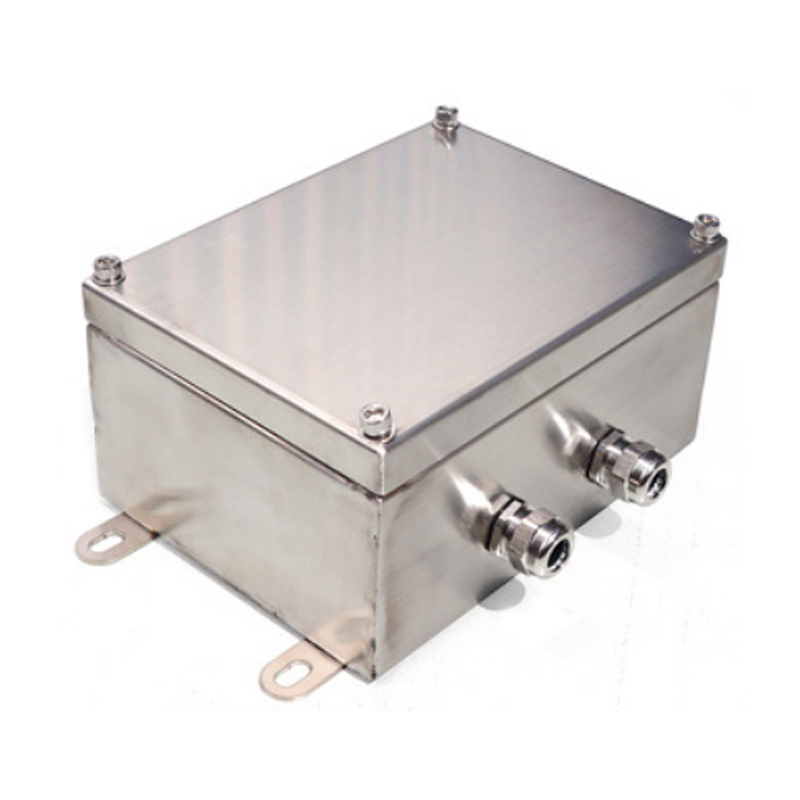

3. CNC Precision Machining - Applicable to Thick or Complex Structures

- For casings with complex structures, large thickness, or requiring extremely high precision, CNC milling is performed directly on stainless steel forgings or thick plates.

- CNC Milling Machine/ Machining Center: Cut metal blocks with high-speed rotating tools to "carve" out the final casing shape. This process can produce highly complex structures and fine features but results in more material waste and higher costs.

4. Surface Treatment

This is a key step to give the stainless steel casing its final appearance and texture.

- Grinding and Polishing: Remove surface scratches and processing marks, achieving effects ranging from matte to mirror finish.

- Sandblasting: Use high-speed abrasive particles to impact the surface, creating a uniform matte frosted texture with a fine hand feel that is not easy to leave fingerprints.

- Wire Drawing: Perform directional linear friction on the surface with abrasive belts or stainless steel brushes to form regular filamentous patterns, which are aesthetically pleasing and can hide minor scratches.

- PVD Vacuum Coating: In a vacuum environment, metal ions such as titanium and chromium are deposited on the stainless steel surface to form an extremely thin and durable coating. It can be coated in various colors such as black, gold, rose gold, and blue, with excellent wear resistance and corrosion resistance. It is a common process for high-end mobile phones and watches.

- Electroplating: A traditional process that can plate chrome, nickel, etc., but with increasingly strict environmental requirements, its application is decreasing.

5. Assembly & QC

- Assemble the processed casing with glass, plastic parts, buttons, internal buckles, screws, etc.

- Conduct comprehensive quality inspections, including:

- Dimensional accuracy inspection (using Coordinate Measuring Machine - CMM)

- Appearance inspection (no scratches, no defects)

- Sealing test (for waterproof products)

- Strength test