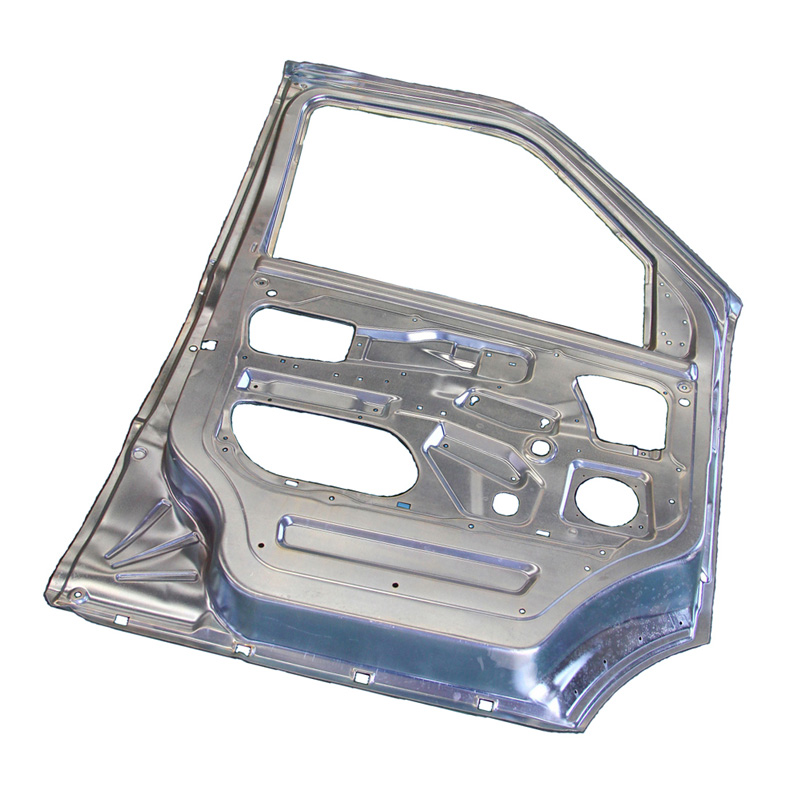

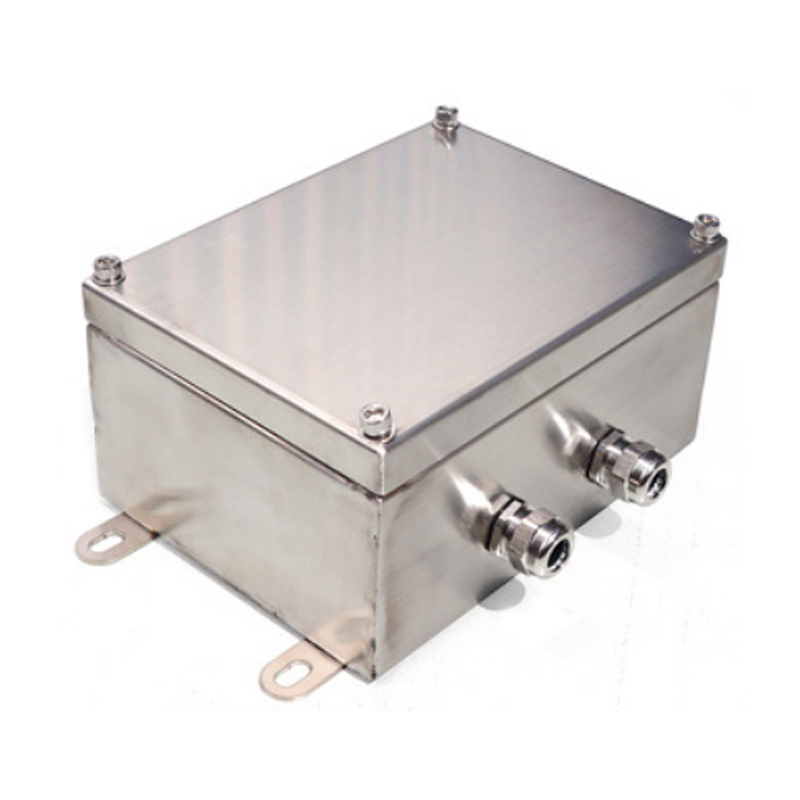

In the ever - evolving world of manufacturing, technological innovation is the key to staying competitive. Yulong Group, a leading name in the production of custom CNC machining parts, stamping parts, laser cutting parts, and auto parts, has recently achieved a significant technological breakthrough in its CNC machining processes.

The company's R & D team has been working tirelessly to improve the precision and efficiency of CNC machining. Through months of research and testing, they have developed a new software algorithm that optimizes the tool path during the machining process. This new algorithm reduces the machining time by up to 20% for complex parts, while also improving the dimensional accuracy by an impressive 15%.

For example, in the production of aerospace - related CNC machining parts, where precision is of utmost importance, this new technology has been a game - changer. Parts that previously took hours to machine can now be completed in a significantly shorter time, without sacrificing quality. The improved accuracy also means that there are fewer rejects, leading to cost savings for both Yulong Group and its customers.

This technological breakthrough is not only a testament to Yulong Group's commitment to innovation but also has far - reaching implications for the industry as a whole. As more manufacturers strive to meet the increasing demands for high - precision, cost - effective parts, Yulong Group's new technology could set a new standard. It may inspire other companies to invest more in R & D to improve their own CNC machining processes.

Moreover, Yulong Group plans to share this technology with its long - term customers, providing them with a competitive edge in their respective markets. By doing so, the company is strengthening its position as a strategic partner for its clients' success, in line with its corporate mission.

In the coming months, Yulong Group will continue to refine this technology and explore its application in other product lines, such as stamping and laser cutting parts. This continuous improvement approach is expected to drive further growth and innovation within the company and the industry at large.