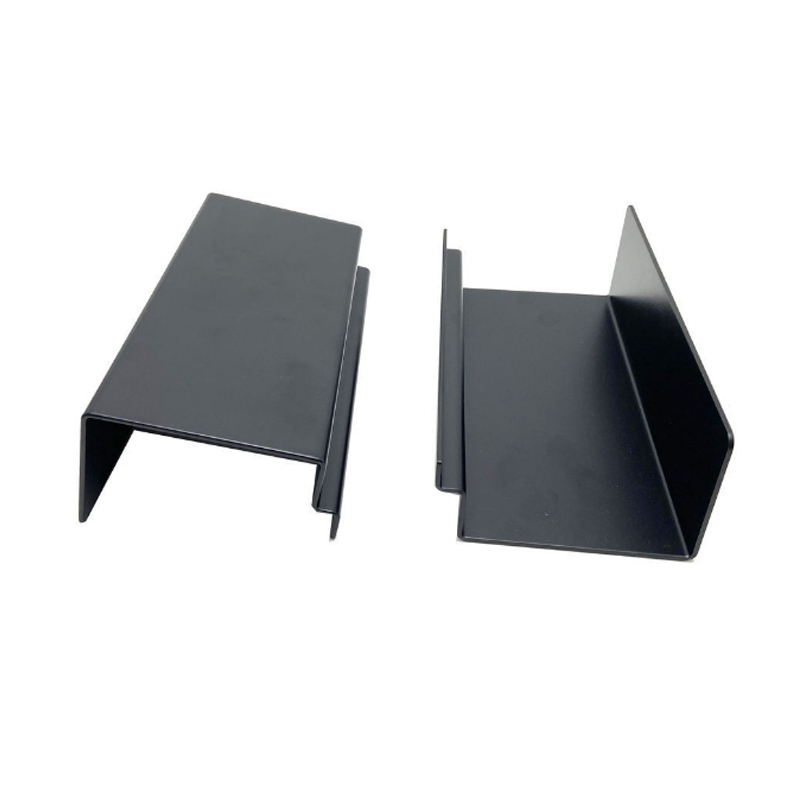

Sheet Metal Stamping Parts

The characteristics of sheet metal pressed parts include the following points:

Firstly, it can efficiently produce large quantities of products and meet the needs of modern industrial production.

Secondly, the precision of sheet metal stamping processing parts is high, which can ensure the quality and stability of the product;Meanwhile, the cost of sheet metal stamping parts is relatively low, which can improve the production efficiency and competitiveness of enterprises.

Finally, the production process of sheet metal pressing parts is environmentally friendly and can reduce environmental pollution for enterprises.

Sheet metal bending is a common metal processing method that can be used to manufacture various items, including parts, tools, and equipment. Here are some tips for sheet metal bending:

Use the correct tools: Using the correct tools can make sheet metal bending easier and more accurate. The most commonly used tools include bending machines, cutting machines, manual shears, and manual benders, etc. Different tools are suitable for different materials and bending angles, so it is necessary to select the appropriate tools according to the specific situation.

Adjust the mold: The mold is a part of the bending machine and is used to support and position the sheet metal material. Adjusting the mold can make it easier and more accurate to bend the sheet metal material. Before using the bending machine, please ensure that the mold is correctly selected and adjusted to ensure the accuracy of material positioning and bending angle.

Use appropriate clamps: Clamps are devices used to fix sheet metal materials on the bending machine. Using appropriate clamps can ensure that the sheet metal materials remain stable and steady during the bending process. When using clamps, please ensure that they are correctly installed and fixed, and make sure that the clamps will not damage the sheet metal materials.

Select appropriate sheet metal materials: Different sheet metal materials have different properties and characteristics. Selecting the right material can make bending easier and more accurate. Commonly used sheet metal materials include steel, aluminum, copper, stainless steel, and titanium. When selecting materials, please consider characteristics such as the strength, hardness, and plasticity of the materials.

Adjust the angle and pressure of the bending machine: The angle and pressure of the bending machine are very important for the quality and accuracy of the bending. Please adjust the angle and pressure of the bending machine according to the type and thickness of the bending material to ensure smooth and accurate bending.

Conduct tests and adjustments: Before performing the formal bending, you can conduct a test bend first and make necessary adjustments. When conducting the test bend, please use the same materials and tools, and conduct multiple tests until the required bending angle and accuracy are achieved.

In the process of sheet metal stamping and forming, it is crucial to select suitable materials. Different materials exhibit different plasticity, strength, and toughness during stamping. Reasonable material selection can effectively improve the forming quality and production efficiency.

Sheet metal stamping dies are one of the most commonly used dies in sheet metal processing, mainly used in processes such as stamping, bending, stretching, shearing, and forming. And the steel for sheet metal stamping dies is the main material for making sheet metal stamping dies, and its quality directly affects the service life, precision, and processing efficiency of the dies.

Ordinary carbon structural steel: It is a low-cost and widely used mold material. It has good machining performance and heat treatment performance, with relatively low hardness and wear resistance. It is suitable for sheet metal products with a small production volume and low precision requirements.

Alloy structural steel: It is a type of steel with alloying elements added, having higher hardness, toughness, and wear resistance than ordinary carbon structural steel. Its machinability and heat treatment performance are also excellent.

Cemented carbide: It is a material made by mixing carbides and metal powders, with extremely high hardness, wear resistance, and corrosion resistance.

Powder high-speed steel: It is a material made by mixing high-speed steel powder with other metal powders. It has excellent properties such as high hardness, high strength, high heat resistance, and high wear resistance. It is suitable for sheet metal products with large production volumes and high precision requirements.

Plastic mold steel: It is a type of mold material specifically used for producing plastic products, with good wear resistance, hardness, and cutting performance. Its price is relatively high, but it can improve the service life of the mold and production efficiency.

The following aspects need to be considered when selecting the appropriate material for sheet metal stamping dies:

Dimensions and load of the die: The larger the die and the greater the load, the higher the hardness of the steel for sheet metal stamping dies is required.

Usage environment of the mold: It needs to have a certain degree of toughness to avoid breakage.

Processing requirements for molds: The processing performance of sheet metal stamping dies directly affects the processing efficiency and cost.

Service life of the mold: The service life of sheet metal stamping dies is closely related to the wear resistance of the materials.

Specification:

| 1.Optional Material: | sheet metal, stainless steel,Aluminum,Copper,Brass. | |||||

| 2.Process Technologies: | sheet metal pressing | |||||

3.Reachable Tolerance: | 0.01-0.1mm | |||||

| 4.Optional surface treatment: | Zinc plated, Nickel plated,Powder coating,painting,brushed. | |||||

| 5.Sample Making : | Rapid prototype according to customer's drawing. | |||||

| 6.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. | |||||

| 7. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 | |||||

Welcome to contact us, we will provide you best price and good quality product.