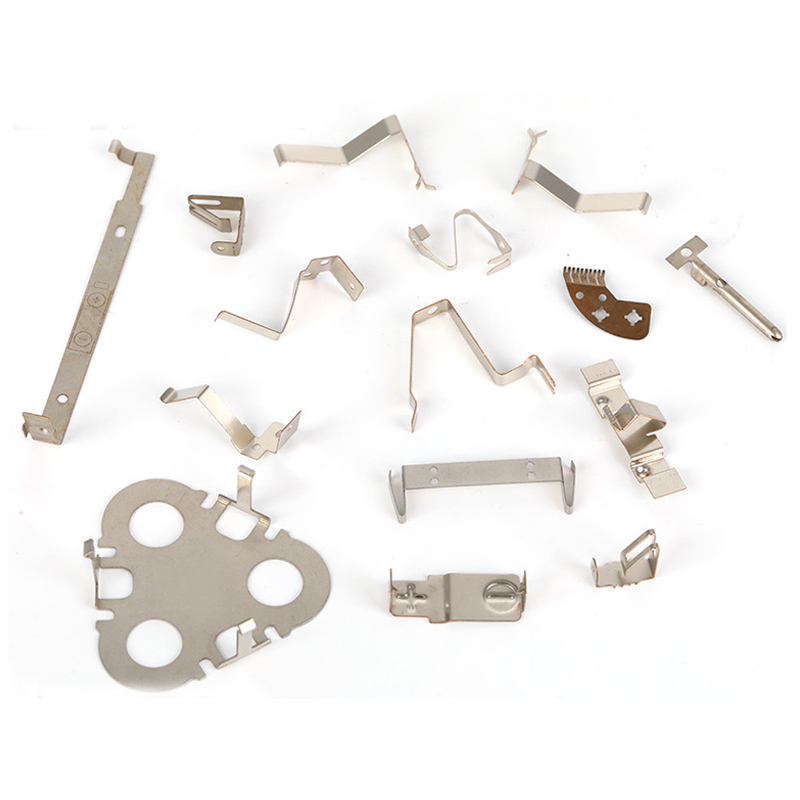

Custom Progressive Die Aluminum Sheet Metal Stamping

Progressive die stamping is a processing method that uses continuous feed fixtures and forming molds to continuously form metal bars, wires, sheets etc. under unidirectional or bidirectional pressure. The basic principle is to form the desired cross-sectional shape through the pressure of the forming die on continuously fed metal materials, thereby achieving precision machining of the material.

2、Our advantages of progressive die stamping technology

1. High efficiency: Progressive die stamping adopts a continuous feed method, which can greatly improve production efficiency, shorten production cycles, and reduce manufacturing costs compared to traditional single piece production processes.

2. High precision: Due to the use of precision molds in the forming process of continuous die stamping, it has high processing accuracy, good dimensional stability, high product consistency, and better performance and quality assurance.

3. Saving raw materials: Due to the excellent forming characteristics of Progressive die stamping, it can reduce the generation of waste, save raw materials, and lower the manufacturing cost of finished products. It has obvious economic benefits for production enterprises and is also an environmentally friendly and energy-saving processing method.

To design custom metal stampings well, a series of design principles and steps need to be followed to ensure that the design not only meets the functional requirements but also can be produced efficiently and economically. The designed stamping parts must meet the requirements of product use and technical performance, and be easy to assemble and repair. This means that designers need to fully understand the final use and performance indicators of the product to ensure that the stamping parts can meet these requirements.

During the design process, it is necessary to consider improving the utilization rate of metal materials, reducing the variety and specifications of materials, and minimizing material consumption as much as possible. This helps to reduce costs and improve resource utilization efficiency.

The designed stamping parts should have a simple shape and a reasonable structure to simplify the mold structure and the number of processes. The goal is to complete the processing of the entire part with the fewest and simplest stamping processes, reduce subsequent other processing steps, facilitate the mechanization and automation of stamping operations, and improve production efficiency. Under the condition of ensuring normal use, try to set the requirements for dimensional accuracy grade and surface roughness grade as low as possible. This contributes to the interchangeability and quality stability of products and reduces the generation of defective products.

During the design, it should be considered to use the existing equipment, tooling and technological processes for processing as much as possible. At the same time, it is also beneficial to prolong the service life of the stamping die and reduce the production cost.

Specification:

| 1.Optional Material: | Steel, stainless steel,Aluminum,Copper,Brass. | |||||

| 2.Process Technologies: | progressive die stamping | |||||

3.Reachable Tolerance: | 0.01-0.1mm | |||||

| 4.Optional surface treatment: | Zinc plated, Nickel plated,Powder coating,painting,brushed. | |||||

| 5.Sample Making : | Rapid prototype according to customer's drawing. | |||||

| 6.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. | |||||

| 7. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 | |||||

If you have demand for progressive die stamping,custom metal stampings, progressive die metal stamping services, Welcome to contact us, we will provide you best price and good quality product.