The metal stamping process is sometimes also referred to as progressive metal stamping. It is a process in which metal sheets or strips are placed on a stamping press, and with the pressure of the stamping press and the action of the die, the metal sheets or strips are processed into precision parts of various shapes. This process relies on specialized tools (i.e., tool and die sets) and equipment (i.e., presses) to form metal sheets and coils into the desired shapes and sizes. The pressure exerted by the press on the workpiece forces the material to conform to the shape formed by the tools and dies.

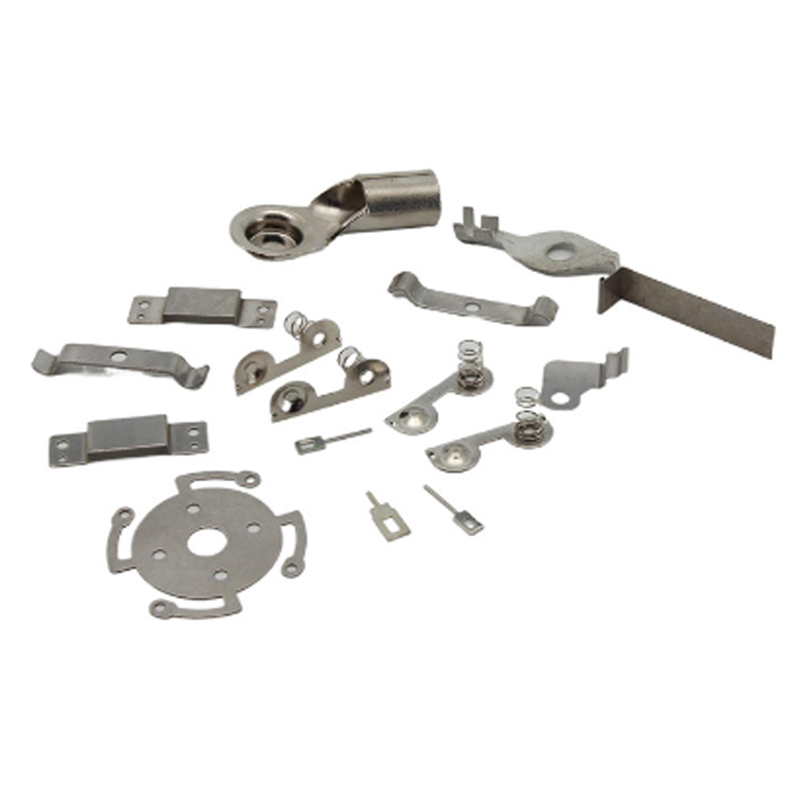

Xiamen Yulong Machinery design and manufacture various stamping press dies as needed, therefore we can produce parts of various shapes, including flat parts, bent parts, embossed parts, etc. It also has good processing capabilities for parts with complex shapes. More complex parts may require multiple strokes, that is, tandem operation.

The stamping machine has high production efficiency and can carry out automated production. It can efficiently produce a large number of parts to meet the customers' needs for mass production. Precision metal stamping is flexible and highly adaptable, which is particularly beneficial for mass production.

Molds can be designed and manufactured with high precision, and the operation largely relies on automated equipment, which can ensure the accuracy and consistency of parts, thereby improving product quality. Its extremely high precision level, even for complex parts, is what distinguishes this process from similar processing options. The metal stamping machines can also perform micro - stamping to produce complex tiny parts.

The process can efficiently produce large quantities of parts and can carry out optimized design of materials as needed, thus saving materials and costs. Meanwhile, as a generally automated process, it reduces the need for manual labor, lowers the error rate, and decreases the material utilization rate and waste in the production process.

This process can efficiently produce large quantities of parts and can carry out optimized design of materials as needed, thus saving materials and costs. Meanwhile, as a generally automated process, it reduces the need for manual labor, lowers the error rate, and increases the material utilization rate and reduces waste in the production process.

Stamping parts are widely used in the following fields:

Used for manufacturing various structural and functional components of car bodies and frames, electrical systems, steering systems, etc., such as some typical automotive parts.

The parts and products in this industry are subject to strict manufacturing requirements and restrictions. Precision stamping can meet its high requirements for part accuracy and quality. Some metal stamped parts and products usually produced for aerospace applications can ensure the safety of personnel on the aircraft, passengers, and the public.

There are many standards in the medical device industry to regulate the manufacturing methods of components. The extremely high standards ensure the safety of doctors and patients. Standard and custom metal stamped parts are present in various medical devices.

Professionals use many different metal stamping parts and products in circuit breakers, distribution boxes, switches, transformers and other key equipment.

Widely used in various commercial and residential appliances, such as some metal stamping parts regularly produced for such applications.

Specification:

| 1.Optional Material: | metal, brass, copper. | |||||

| 2.Process Technologies: | precision metal stamping | |||||

3.Reachable Tolerance: | 0.01-0.1mm | |||||

| 4.Optional surface treatment: | Zinc plated, Nickel plated,Powder coating,painting,brushed. | |||||

| 5.Sample Making : | Rapid prototype according to customer's drawing. | |||||

| 6.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. | |||||

| 7. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 | |||||

If you have demand for stamping parts,metal stamping parts,precision stamping parts,precision metal stamping services, Welcome to contact us, we will provide you best price and good quality product.