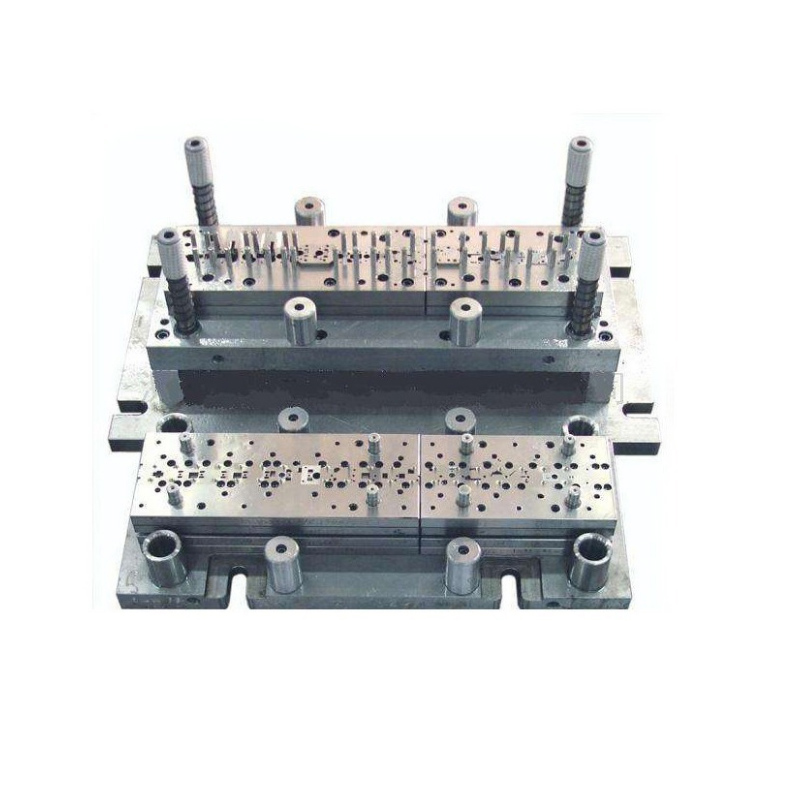

A progressive die is a cold stamping die that uses strip-shaped stamping raw materials and simultaneously completes multiple stamping processes at several different stations on a single die during one stamping stroke of a press. This process allows the material strip to always move in one direction. Each time the die completes a stamping operation, the strip moves at a fixed distance until the product is finished.

We offer series of progressive die with reliable quality and competitve prices.

Features and advantages of the progress ive die:

High production efficiency: It can complete multiple processes in a single stamping stroke, significantly improving production efficiency.

High product precision: Thanks to the precision machining and multiple calibrations of the mold, high precision of the products can be ensured.

Good process stability: The entire process flow is standardized, which reduces the influence of human factors and improves the stability of the process.

Suitable for multiple industries: Widely used in industries such as electronics, automotive, and aerospace.

Maintenance methods for progressive dies

The maintenance of progressive dies is a meticulous and important process, which includes maintenance work in multiple aspects to ensure the long-term stable operation of the dies and the stability of product quality.

Maintenance of punch and die

Disassembly and Inspection: When disassembling the punch, it is necessary to pay attention to checking the smoothness of the stripper block and the die, as well as whether the clearance between the stripper block and the die is uniform. Similarly, when replacing the die, it is also necessary to check whether the clearance between the die and the punch is uniform.

Padding and Length Check: To reduce the wear of the punch, it may be necessary to add washers to achieve the required length. At this time, the effective length of the punch should be checked to ensure it is sufficient.

Assembly Precautions: When assembling the female die, it should be placed horizontally. Then, place a flat steel block on the surface of the female die and gently tap it into place with an aluminum rod. Avoid forcing it in obliquely. The bottom of the female die should be rounded. After the assembly is completed, it is necessary to check whether all components are installed correctly and whether the mold needs to be clamped tightly.

Disassembly and Inspection: When disassembling the stripper plate, you can use two screwdrivers to pry it open evenly and then take it out evenly by hand. If disassembly is difficult, you should check whether the mold is cleaned thoroughly, whether all the screws are removed, and whether there is any damage to the mold.

Assembly and Maintenance: When assembling the stripper plate, first clean the punch and the stripper plate, and apply grease between the locating pin and the punch guide. After successfully placing them, press it with your hand several times. If there are steel chips on the fixed plate, check whether the seats on the stripper side plate are sufficient.

Gap inspection and adjustment: Due to the damage of the mold core, the positioning holes of the mold core may cause excessive or uneven gaps after assembly. The appropriate gap adjustment can be carried out by checking the cross - section condition after laser cutting. If the gap is too small, there will be fewer cross - sections; if the gap is too large, there will be more cross - sections and larger burrs. After adjustment, it should be recorded as much as possible, or marks should be made on the edge of the female mold for subsequent maintenance operations.

Inspection of locating pins and guide posts: The fit clearance of locating pins and guide posts should be regularly checked, as well as whether there are signs of scalding or damage, and whether the lubrication of the mold guide is normal.

Daily inspection: In daily production, attention should be paid to checking whether the punching machine and the mold are in a normal state, such as the supply of punching oil and the lubrication of the guiding parts. Inspections before the mold is installed on the machine, inspections of the cutting edges, and confirmation of the locking of all parts are all necessary preventive measures.

Through the above maintenance measures, the service life of the progressive die can be effectively extended, and the product quality and production stability can be improved.

Specification:

| 1.Optional Material: | Mould steel. | |||||

| 2.Mould: | progressive die | |||||

| 3.Die try out | Die trial to ensure it in good operation. | |||||

| 4.Quality Guarantee: | base on the order quantity, according to die life. | |||||

If you require progressive die,progressive stamping die design service , Welcome to contact us, we will provide you best price and good quality of metal stamping dies.