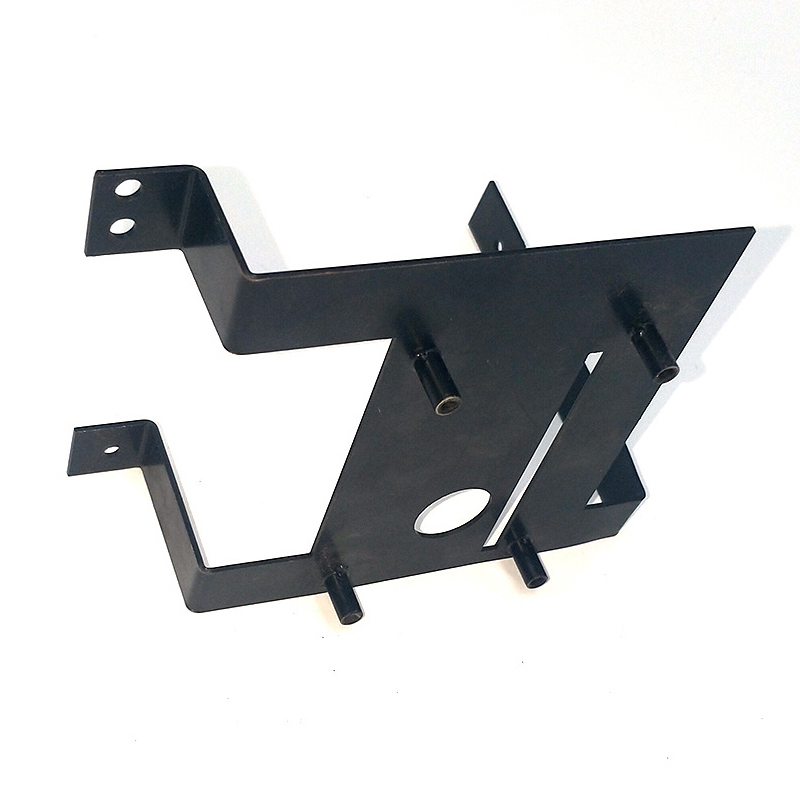

Sheet Metal Steel Stamping Parts

Metal parts stamping is widely used as a high-precision and efficient processing method. It is suitable for large-scale production as it can create complex shapes in a short period of time while utilizing the mechanical strength of metals. In addition, when improving the quality of stamping processing, we take the following points into consideration.

1.Choose the appropriate metal material.

The hardness and elastic modulus of the materials used are directly related to the quality of stamping processing, so it is important to choose materials according to their purpose.

2. Require appropriate mold selection and design.

It is important to choose the most suitable mold based on the workability of the metal and the desired shape. By designing to minimize friction and deformation during the machining process, quality can be improved.

3. Set appropriate processing conditions.

By setting appropriate processing conditions such as pressure and temperature, the deformation and tensile strength of the metal can be controlled.

4. Quality improvement.

In order to improve quality, it is necessary to correctly understand these key points and conduct checks and adjustments in each process. By maintaining a constant awareness of quality improvement, you will be able to achieve higher quality stamping steel parts.

In response to the improvement of the processing technology for sheet metal stamping parts, combined with industry practices and cutting - edge technologies, we propose the the following optimization directions and specific measures:

Predict the springback amount through numerical simulation (such as finite element analysis), and design the compensation surface of the mold to correct the geometric errors of the parts.

Adopt the Variable Binder - Holder Force (VBHF) technology to dynamically adjust the pressure according to different forming stages, reducing defects caused by uneven material flow.

Decompose the multi - process stamping (such as incremental forming) process and optimize the process sequence to reduce material stress concentration. For example, punch holes first and then bend.

For deep - drawn parts, optimize the lubricant and adjust the blank - holder clearance to reduce the risk of cracking.

Adopt the RP - AMS process (Rapid Prototyping + Arc Metal Spray) to shorten the die development cycle and reduce costs by 30% - 50%, which is suitable for small - batch trial production.

Introduce high - hardness coatings (such as tungsten carbide) to extend the die life and reduce downtime for maintenance.

Use topology optimization technology to reduce redundant materials in the die. At the same time, verify the structural strength through finite element analysis to achieve energy consumption reduction and production efficiency improvement.

Specification:

| 1.Optional Material: | Steel,metal,Aluminum,Copper,Brass. | |||||

| 2.Process Technologies: | metal parts stamping | |||||

3.Reachable Tolerance: | 0.01-0.1mm | |||||

| 4.Optional surface treatment: | Zinc plated, Nickel plated,Powder coating,painting,brushed. | |||||

| 5.Sample Making : | Rapid prototype according to customer's drawing. | |||||

| 6.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. | |||||

| 7. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 | |||||

If you have demand for stamping steel parts,sheet metal stamping parts, metal parts stamping services, Welcome to contact us, we will provide you best price and good quality product.