CNC (Computer Numerical Control) milling is a high-precision machining process. It involves cutting workpieces with a computer-controlled machine and is widely used in modern manufacturing. To create high quality CNC milling parts, Xiamen Yulong Machinery implement the following steps:

1. Keep high precision and dimensional stability

CNC milling can achieve machining accuracy at the micron level, ensuring the consistency of each part of metal CNC mill. This high-precision machining ability makes CNC milling an ideal choice for manufacturing precision milling parts.

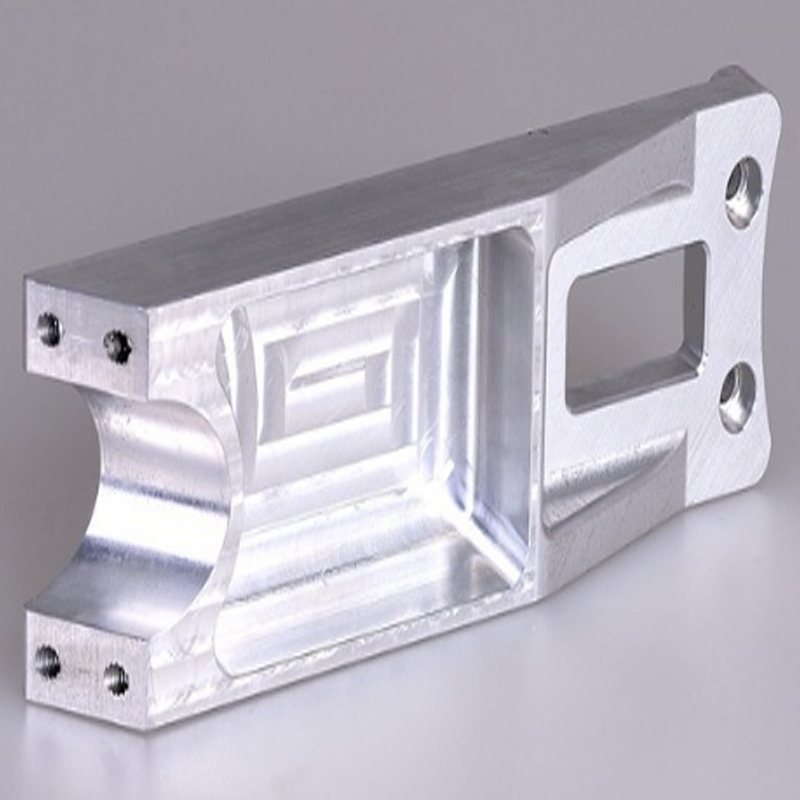

2. Always process complex shapes

Whether it is a simple plane or a complex three-dimensional structure, our CNC milling can handle it with ease. This flexibility makes our CNC milling suitable for the manufacturing of CNC milling machine parts with various shapes and complexities.

3. Maintain high-efficiency production capacity

Due to its high degree of automation, CNC milling can significantly improve production efficiency and shorten the delivery cycle. This not only enhances production efficiency but also improves metal CNC mill product quality and customer satisfaction.

4. Make applicable material selection

Selecting suitable materials is the primary consideration in precision metal machining. For example, aluminum alloy is favored for its light weight, corrosion resistance, and machinability, therefore CNC mill aluminum parts are popluar products in the market. Ensure that the selected materials meet the requirements of the parts, and consider their mechanical properties and durability.

5. Optiimze CNC milling parts production process

Xiamen Yulong Machinery use advanced CNC machining equipment and process technologies can improve machining accuracy and efficiency. Employing suitable cutting tools, cutting parameters, and coolants can reduce thermal deformation and surface roughness during the machining process, thereby enhancing the quality of parts.

6. Keep strict quality control

By strictly controlling dimensional deviations, surface quality, and shape accuracy during the machining process, the precision and consistency of the parts can be guaranteed. Using advanced measuring equipment and quality management systems can monitor and adjust the machining process in real time to ensure that each part meets the customer's requirements.

Specification:

| 1.Optional Material: | Metal,Aluminum,Copper,Brass. | |||||

| 2.Process Technologies: | CNC machining center,CNC Milling, CNC Turning, CNC lathe,at 2-5 axis. | |||||

3.Reachable Tolerance: | 0.01-0.1mm | |||||

| 4.Sample Making : | Rapid prototype according to customer's drawing. | |||||

| 5.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. | |||||

| 6. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 | |||||

If you have demand for precision cnc milling parts, metal cnc milling, aluminum cnc mill, please send an inquiry freely!