Xiamen Yulong Machinery offer custom CNC milling services.

Here are some advantages of high-precision CNC custom milled parts:

Meet the needs of multiple industries.

Medical field: In today's rapidly developing medical technology, the diagnosis, treatment, and rehabilitation of diseases all rely on high - precision medical equipment. High - precision CNC milling parts, as the core elements in the manufacturing of medical equipment, can ensure the precise operation of medical equipment and provide reliable support for the medical industry.

Aerospace and Aviation Field: This field has extremely high requirements for the precision of parts. High-precision CNC milled parts can ensure the safety and reliability of aerospace equipment and meet its complex working environment and high-performance requirements.

Electronics field: Electronic products are continuously evolving towards miniaturization and high performance. High-precision CNC milling parts can meet the requirements of the internal precision structures of electronic devices, improving the performance and stability of electronic products.

High-precision metal CNC mill parts can take the quality of products to a higher level and reduce product failures and the defective rate caused by issues with part precision. In the market competition, high-quality products are more likely to win the favor of customers, thereby enhancing the market competitiveness of enterprises.

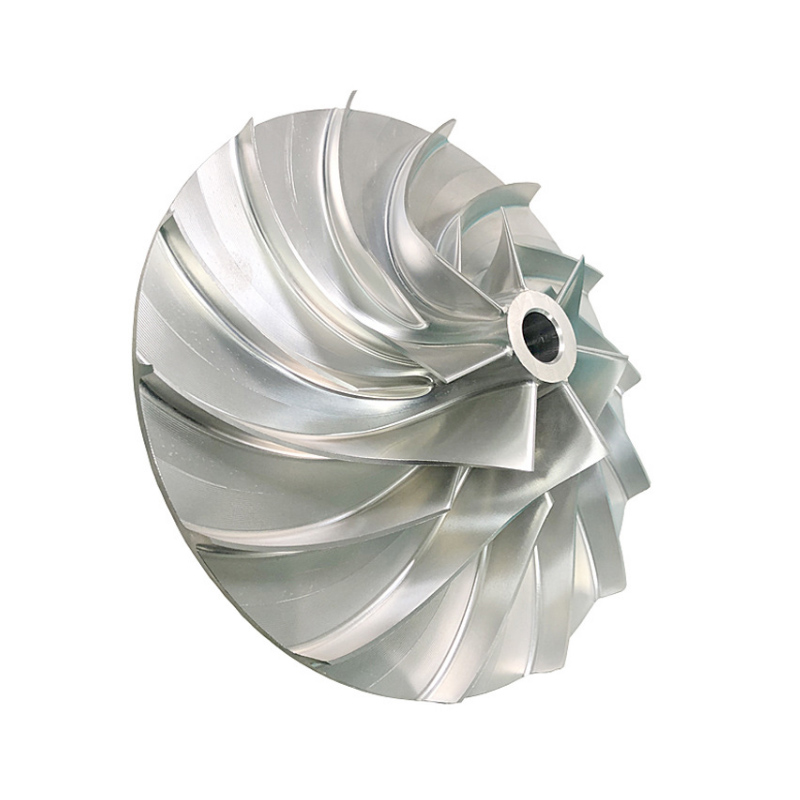

Advanced CNC milling equipment has higher precision and stability, which can better ensure the machining accuracy of parts. For example, a CNC milling machine with 5-axis linkage function can perform machining in multiple directions, reducing the number of clamping operations and thus improving the machining accuracy of parts.

A reasonable processing technology is crucial for ensuring the precision of parts. Factors including the selection of cutting tools, the setting of cutting parameters, and the planning of machining paths will all affect the precision of parts. For example, selecting appropriate cutting tools can reduce the impact of cutting force on parts, and an optimized machining path can avoid the damage to part precision caused by repeated machining.

The skill level and experience of operators also have an impact on the precision of parts. Skilled operators can flexibly adjust the equipment and process parameters according to different part requirements and processing conditions, thus ensuring the precision of parts.

Specification:

| 1.Optional Material: | Steel, stainless steel,Aluminum,Copper,Brass. | |||||

| 2.Process Technologies: | CNC machining center,CNC Milling, CNC Turning, CNC lathe,at 2-5 axis. | |||||

3.Reachable Tolerance: | 0.01-0.1mm | |||||

| 4.Sample Making : | Rapid prototype according to customer's drawing. | |||||

| 5.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. | |||||

| 6. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 | |||||

If you have demand for custom cnc mill, custom cnc milling service,custom milled aluminum, Welcome to contact us, we will provide you best price and good quality product.