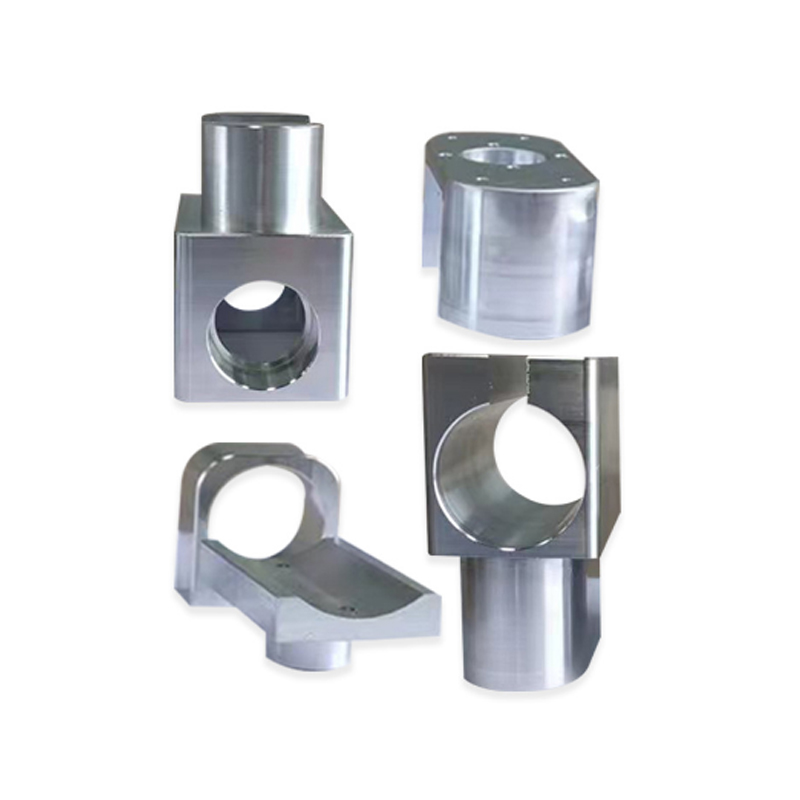

If you have demand for CNC machining metal parts, welcome to contact us. We will provide you with the best price and quality products.

| 1.Optional Material: | Steel, stainless steel,Aluminum,Copper,Brass. |

| 2.Process Technologies: | CNC machining center,CNC Milling, CNC Turning, CNC lathe,at 2-5 axis. |

| 3.Reachable Tolerance: | 0.01-0.1mm |

| 4.Sample Making : | Rapid prototype according to customer's drawing. |

| 5.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. |

| 6. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 |

Machining metal parts introduction

The benefits of using CNC machining to process aerospace parts

CNC machining is a perfect choice for manufacturing cnc aerospace parts due to its numerous advantages. Its advantages include:

1.CNC aerospace parts Create lightweight components

In the field of flight technology, weight is a crucial factor. CNC machining can manufacture thin-walled structures and components using sturdy and lightweight materials to meet this demand. This makes it very suitable for manufacturing components in the aerospace industry.

2.Machining aerospace parts Minimum part error

Parts manufactured using traditional/conventional manufacturing methods are prone to failure due to dimensional errors introduced by human factors. However, through precision CNC machining, this situation is almost impossible to occur, as this manufacturing process ensures that aerospace parts meet strict dimensions, tolerances, and performance standards, while ensuring high performance and preventing part failures.

3.Machining metal parts High precision and precision

Precision is the hallmark of CNC machining, as it creates high-precision and consistent parts. CNC machine tools are precise to a few micrometers with very small errors. The use of CNC machining in the aerospace industry can ensure the production of parts that are precisely aligned with aircraft parts, thereby preventing the failure of general parts and resulting property damage.

4.CNC machining aircraft parts Consistency and efficiency

The use of CNC machining in the aerospace industry can improve manufacturing efficiency. This process is automated, improving production speed, reducing time, while ensuring that the produced parts are accurate and consistent. With this precision and consistency, there is minimal waste, and parts production rarely requires rework due to inaccurate dimensions.

custom cnc machining services

cnc aerospace parts

custom cnc machining services

Are you looking for a reliable and quick-turn provider of Custom CNC machining services? You’ve come to the right place! Using state-of-the-art CNC technologies, our team of machinists, engineers, and quality control experts works together to ensure your products are done right and shipped on time. We have designed our ISO 9001: 2015 certified CNC manufacturing facility for rapid prototyping and low-volume production of a broad range of components. Our Custom CNC machining services also complement our other manufacturing capabilities (like 3D printing and injection molding), providing you with an all-encompassing manufacturing solution. We produce simple and complex precision machined parts in a broad range of materials and surface finishes.

What is cNC machining aircraft parts?

Computer numerical control (CNC) machining is a subtractive manufacturing processㅡwhich means it uses machine tools to remove portions of material from a workpiece till it forms the desired shape.

A computer program (also called G-code) controls the sequence by which CNC machine tools (or workpiece) move against each other to create the desired parts.

Standard CNC machines include multi-axis CNC milling machines, lathes (or turning machines), and routers. Although all CNC machine types rely on computer instructions to perform subtractive manufacturing, they differ slightly in their modes of operation.

For instance, CNC milling machines operate by holding the workpiece in place as the cutting tool rotates against it. In contrast, CNC turning machines create parts by holding the cutting tool in place as the workpiece rotates against it.

Why Choose Custom CNC Machining

CNC machines can create a broad range of features and high-precision parts. For instance, CNC milling machines are ideal for producing cavities, angled shapes, holes, and slots.

In contrast, CNC lathes are suitable for creating cylindrical shapes or parts that are symmetrical near their axis.

Nevertheless, CNC milling and turning machines can achieve tolerances as tight as ±0.001mm.

They are also compatible with a broad range of materials, including metals and plastics, so long as these materials are available in blocks. This is not the case with additive manufacturing technologies (like 3D printing), which are only compatible with plastics and a few metals.

FAQ

Why choose us over other suppliers?

1).Over 25 year’s production experience, proficient in the producing many different kinds of metal parts and can find the best way to reduce cost for customers.

2) With stamping, 2D laser cutting, 3D laser cutting, CNC bending, pipe bending, CNC processing, CNC turning, robot welding, assembly and other complete production technology, We can provide custom cnc machining services,cnc aerospace parts,machining aerospace parts,machining metal parts,cnc machining aircraft parts one-stop custom machining service.

3). With a professional R & D team of over 30 peoples, Can provide design, development and technical solutions for customers.

4).Not only accept big quantity order, but also small quantity order;

5).Quick prototype, Free sample.

6). Ensure quality and delivery time.