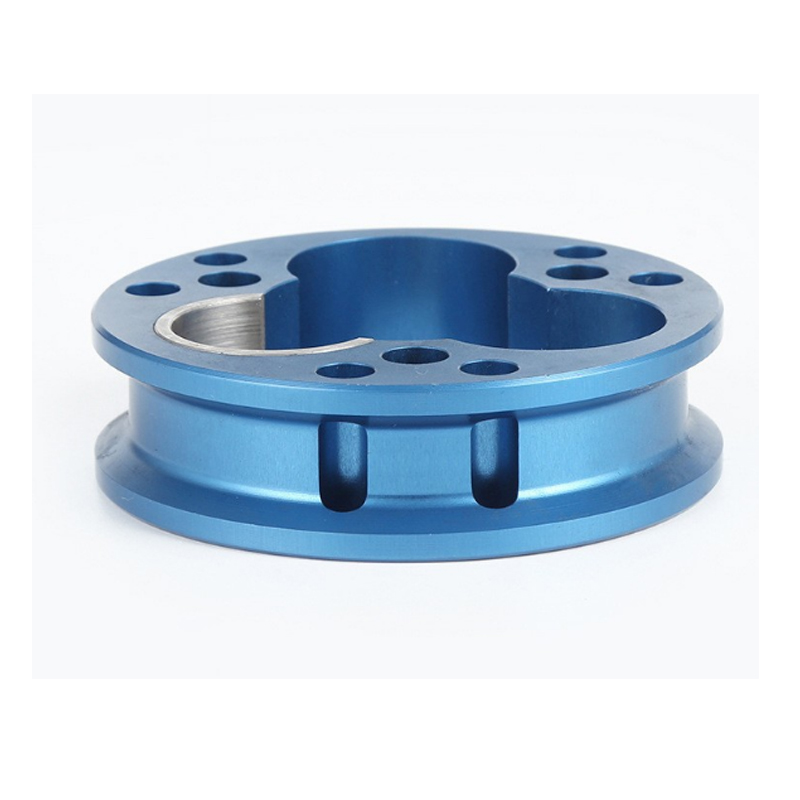

Aluminum CNC parts series

As one of professional aluminum CNC parts suppliers, when doing the aluminum parts machining , Xiamen Yulong Machinery follow the following steps to ensure the quality and efficiency:

1. Choose the appropriate tool: Aluminum alloy has lower machining hardness but higher plasticity and thermal conductivity. Therefore, selecting appropriate cutting tools is crucial for improving machining efficiency and quality. Common cutting tools include high-speed steel cutting tools, hard alloy cutting tools, ceramic cutting tools, etc.

2. Control processing parameters: The processing temperature of aluminum alloy is relatively low, which is prone to problems such as scratches and thermal deformation. Therefore, it is necessary to strictly control the machining parameters, such as cutting speed, feed rate, cutting depth, etc., to ensure stability and efficiency during the machining process.

3. Maintain appropriate lubrication conditions: During the aluminum alloy processing, it is necessary to maintain appropriate lubrication conditions to reduce tool wear and thermal damage to the workpiece surface. Common lubrication methods include hydraulic oil, cutting fluid, etc.

4. Pay attention to the setting of cutting parameters: The selection of cutting parameters is one of the key factors affecting machining quality. Excessive cutting parameters, such as feed rate and cutting depth, can generate excessive heat in the cutting area, leading to thermal expansion and deformation of aluminum alloy materials. Therefore, suitable cutting parameters should be selected according to the actual situation to reduce friction and heat.

5. Ensure sufficient cooling: Cooling can effectively lower the processing temperature and reduce the deformation of aluminum alloy materials. If the cooling is insufficient, the surface temperature of the workpiece will rapidly increase and last for a long time, ultimately leading to deformation. Therefore, adequate cooling shall be ensured when processing aluminum alloy, such as using water spray or atomizing spray system to make the processing area well cooled.

We leverage effective methods for quality control of machined aluminium part as follows:

1)Select aluminum alloy materials with corresponding properties according to the functional requirements of the parts. For example, for parts that require high strength, aluminum alloys with higher strength should be selected; if there are requirements for the corrosion resistance of the parts, aluminum alloy materials with good corrosion resistance need to be chosen. When performing aluminum parts maching, Xiamen Yulong Machinery will match the material properties according to the functional requirements of the parts.

2) Ensure that the purchased raw materials fully meet the customer's specification requirements. Through in - depth analysis of the 3D drawings, samples and specific requirements provided by the customer, select the most suitable aluminum alloy materials to guarantee that the quality of the products processed later can meet the customer's expectations of reliable CNC machined aluminum parts.

3) Conduct real-time vibration monitoring and tool wear early warning during the machining process. By monitoring the operating status and machining parameters of the equipment in real-time, problems can be detected and adjusted in a timely manner. For example, when tool wear is detected, the tool should be replaced promptly to avoid affecting the part quality due to tool problems.

4) Construct a full - process quality traceability system for CNC machined aluminum parts through high - precision verification methods such as three - coordinate measurement and surface roughness detection. In this way, when product quality problems are found, it is possible to trace back to the specific processing links and responsible persons, which facilitates the timely solution of problems and the improvement of processes.

5) We have a professional technical team and a comprehensive pre - sales and after - sales service system. The engineer team has been deeply involved in the machinery manufacturing field for many years. They are familiar with industry standards and processing technologies of CNC mill aluminum, and can quickly understand customers' technical requirements, convert drawings and parameters into executable processing plans. Moreover, they can monitor the processing progress and quality data in real - time during the production process, and conduct rapid analysis and adjustment for sudden problems.

6) Focus on transforming technical experience into customer value. Through the analysis of cross - industry cases, extract process templates suitable for parts of different materials and different complexities, and continuously optimize details such as clamping schemes and cooling systems. Regularly summarize and analyze the production process and product quality, and continuously improve the process and management methods to enhance the quality control effect.

Specification:

| 1.Optional Material: | Aluminum 6061,6063,7075. | |||||

| 2.Process Technologies: | CNC machining center,CNC Milling, CNC Turning, CNC lathe,at 2-5 axis. | |||||

3.Reachable Tolerance: | 0.01-0.1mm | |||||

| 4.Sample Making : | Rapid prototype according to customer's drawing. | |||||

| 5.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. | |||||

| 6. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 | |||||

If you have demand for aluminum cnc parts, aluminum parts cnc machining,cnc machined aluminum parts, cnc mill aluminum, Welcome to contact us, we will provide you best price and good quality product.